Engine vibrations can not only be uncomfortable, but they’re also hazardous.

That’s why manufacturers specify scheduled engine maintenance and the FAA issues mandates related to engine safety. These typically include testing requirements and allowable limits of engine vibration.

JSA’s PT6 Vibration Analysis keeps track of recommendations and mandates that affect our clients and their aircraft. With cutting-edge technology, detailed logs that track the life of an engine, and our team of FAA certified mechanics, we’re able to locate imbalances that are the root cause of vibration.

An engine’s components have an asymmetrical mass distribution that causes shaking. PT6 engine vibration analysis finds what needs service and where. JSA’s engineers balance or replace rotors and worn parts that may require repairs after several hours in the sky or entire engines. JSA is a proud distributor of Extex Engineered Products and Southwest Turbine parts, manufacturers aviators trust.

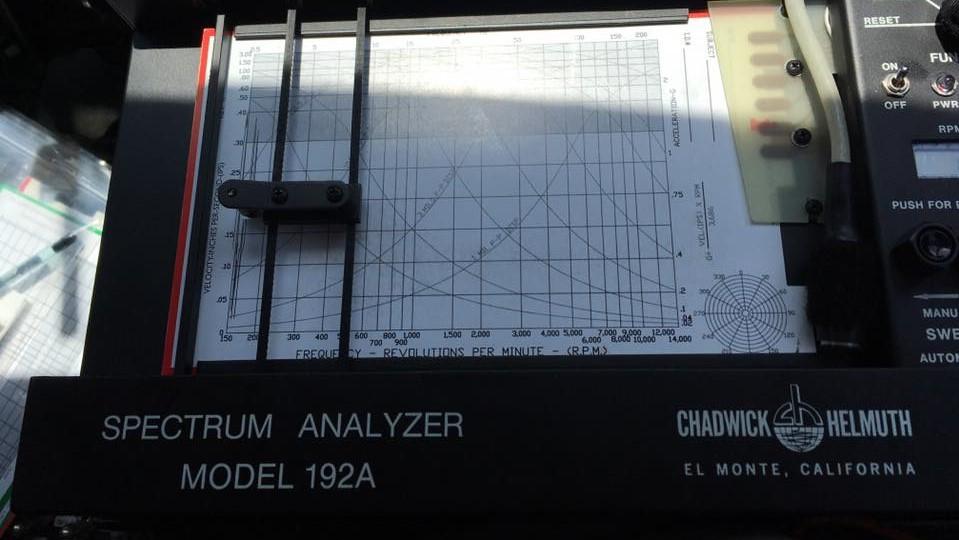

Our specialists also measure and inspect your aircraft’s displacement, velocity, and acceleration to prevent any damage its motor may experience due to vibration.

With over 35 years of history in experienced engineering, JSA’s PT6 field maintenance offers a full list of services is available anywhere they’re necessary: troubleshooting, in-field repair, rigging, hot section inspections, borescope inspections, etc. We also keep detailed records of our clients’ crafts to ensure they receive preventative maintenance to ensure our clients never get stranded far from home.

Trust Jetset Airmotive’s PT6 engine vibration check, we won’t let you do – literally.